Material Selection

Our Engineering and Development team works in close coordination with our customers to assist with the selection of materials to be used in plastic injection molding processes.

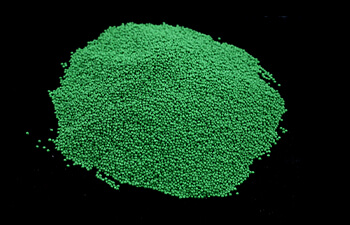

For over three decades we have worked with a wide range of plastic materials ot manufacture products of exacting standards and specifications. Some of the commonly used polymers and resins are PPCP, Random Copolymer, Homopolymer, PA66.

Over the course of five decades, we have worked with a wide array of resins and plastics materials to manufacture products to meet customer specifications.

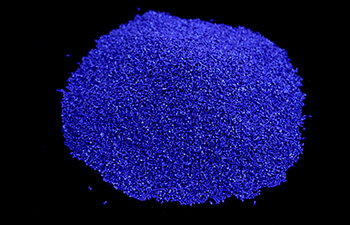

Polyamide 66 (PA66) and polycarbonate (PC) are the resins used most frequently.

In addition to bulk resins, we purchase a variety of other materials, including compounded and master-batched resins, magnets, stamped metal components, machined metal inserts, and packaging materials.

- Acrylonitrile Butadiene Styrene (ABS)

- Polyamide 6 (PA6)

- Polyamide 66 (PA66)

- Polycarbonate (PC)

- Polyether Sulfone (PESU)

- PolyPropolene (PP)

- Styrene Acrylonitrile (SAN)

- Thermoplastic Rubber (TPR)

BTPL maintains strong relationships with manufacturers and distributors of materials used in our manufacturing processes. We are actively engaged in ongoing dialogue with suppliers in order to ensure that we are able to offer clients competitive pricing and reduce the risk of supply disruption.