Technology And Automation

Forward-thinking solutions for Plastics Manufacturing

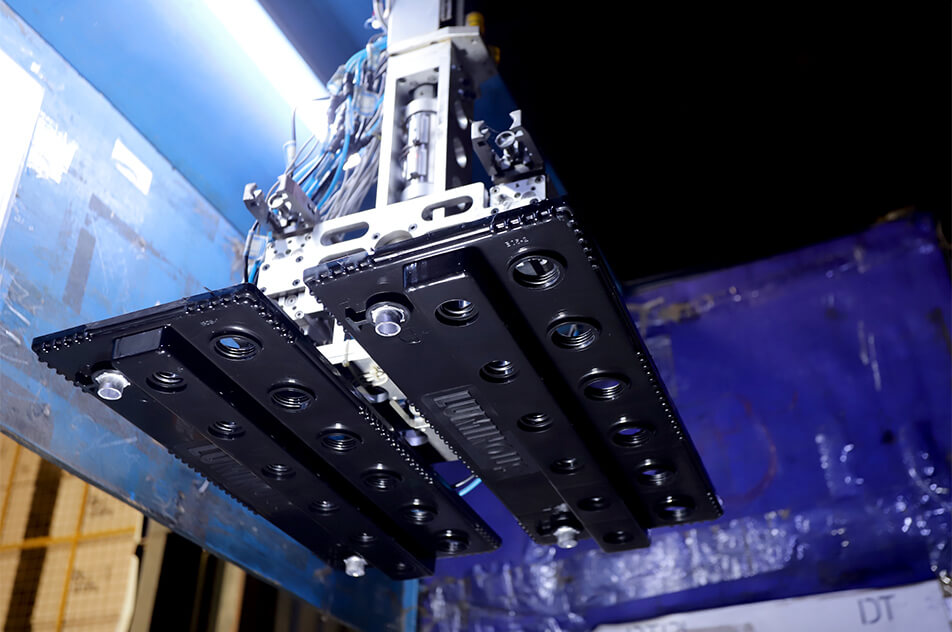

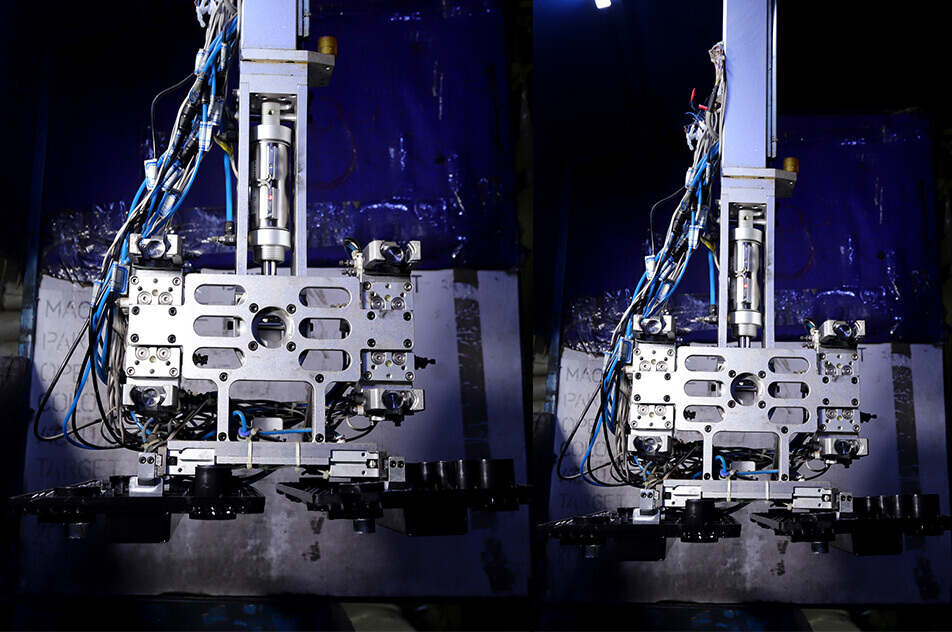

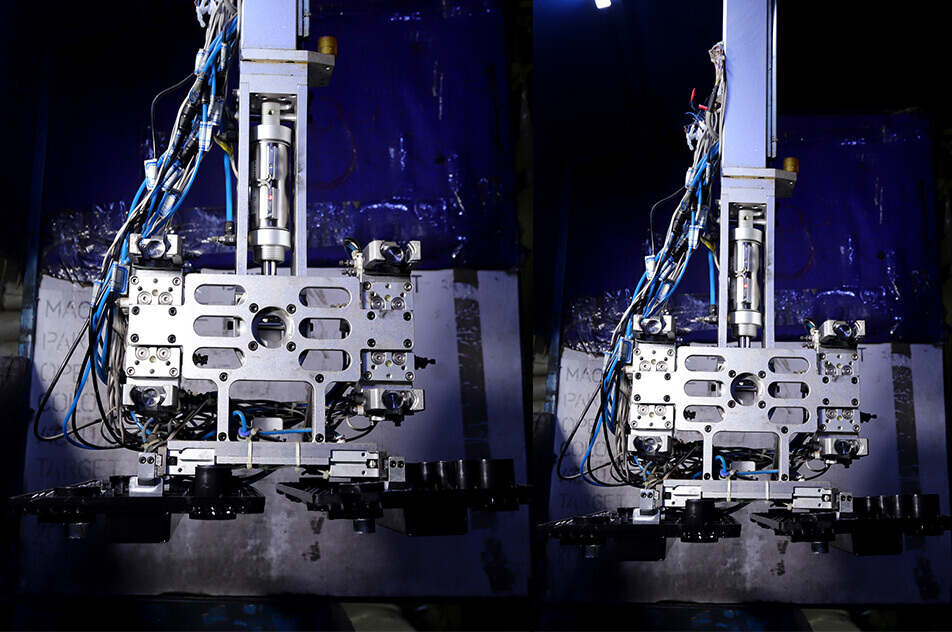

Technology is in our company’s name. Our business was founded on a commitment of continuous improvement, which means always advancing equipment, processes and knowledge. BTPL has been one of the pioneers to engage automation for insert molding applications for Battery Lid molds, which were subsequently ramped up to a twin cavity tool after tasting success, thus increasing the productivity.

Having embraced ERP system for planning, procurement, purchase, manufacturing and supply chain modules, BTPL offers a completely professional ecosystem in its dealings with customers who also have access to real time information and thus reducing unnecessary dependence on human resources.

BTPL now boasts of two all electric machines of 180 tons which greatly enhance our ability to produce plastic parts with extremely high precision and also offer considerable energy savings.

BTPL has been investing a lot of resources into automation, new ancillary equipment and new technologies. This has been done in order to have exacting precision in the dimensions, aesthetics and mechanical properties of the components and also to better the efficiency.

BTPL employs robotic technology from Switek Inc of the PRC.

After initial success in the robotic installation the scale is now being ramped up to cover almost half of our installed machines with insert molding requirements. This will ensure that mistake proofing is achieved and increase the efficiency considerably.